Precision Auto Components

"The automated deburring system reduced our post-processing time by 40% while maintaining ±0.02mm consistency. The ROI was achieved within just 8 months of operation."

With 15+ years of industry expertise, DYYRENT leads the market in advanced deburring solutions. We specialize in engineering precision machines that deliver perfect edge finishes on flat metal surfaces. Our European-designed technology is trusted by manufacturers in 60+ countries to increase production efficiency, reduce labor costs, and ensure consistent quality in every piece.

Precision in Motion

With 15+ years of expertise, DYYRENT specializes in high-precision deburring machines for flat metal surfaces. Our European-engineered technology ensures smooth, flawless edges and extended machine lifespan. Certified to ISO & CE standards with 3-year warranty coverage.

We engineer custom deburring solutions for any flat metal application - from delicate components to industrial-scale production. Our machines handle steel, aluminum, and alloys with micron-level accuracy, eliminating sharp edges while preserving material integrity.

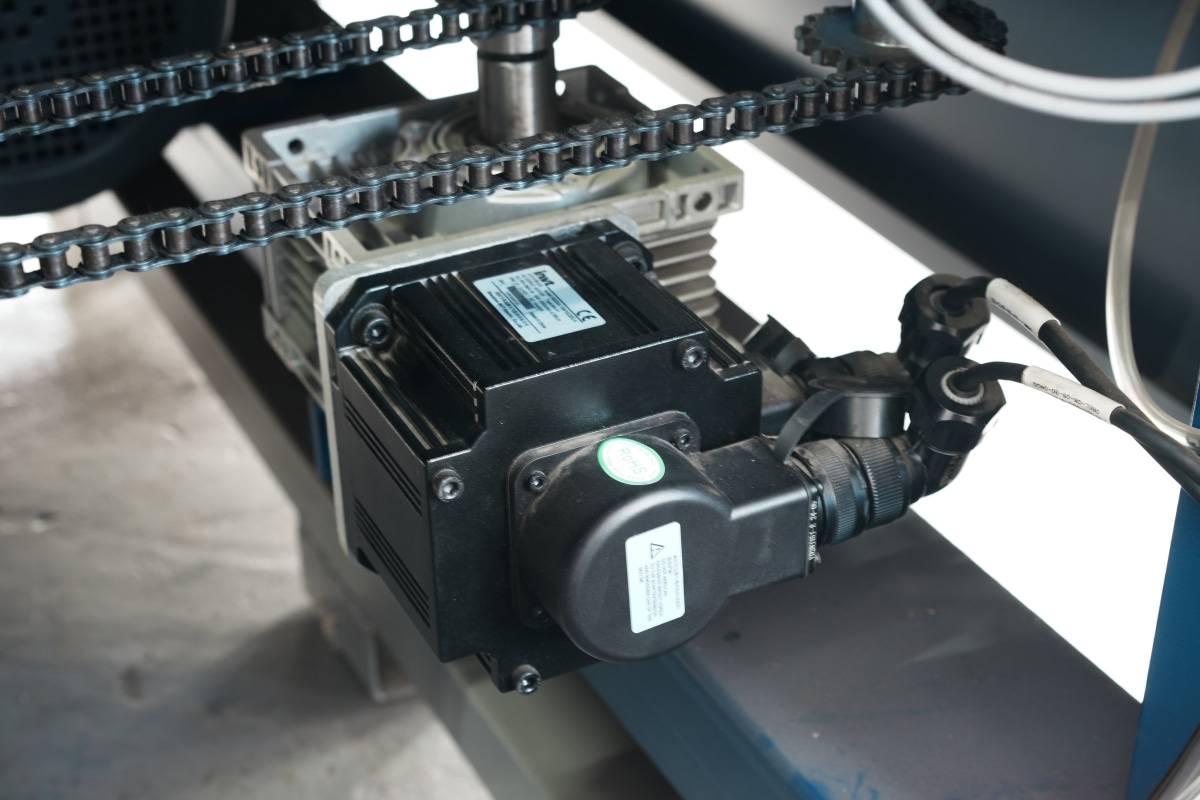

Our R&D team continuously advances deburring technology with automated feeding systems and AI-driven quality control. Backed by global technicians, we provide 24/7 remote diagnostics, on-site maintenance, and operator training programs.

Contact us for a price

Speak To Deburring Machine Specialist

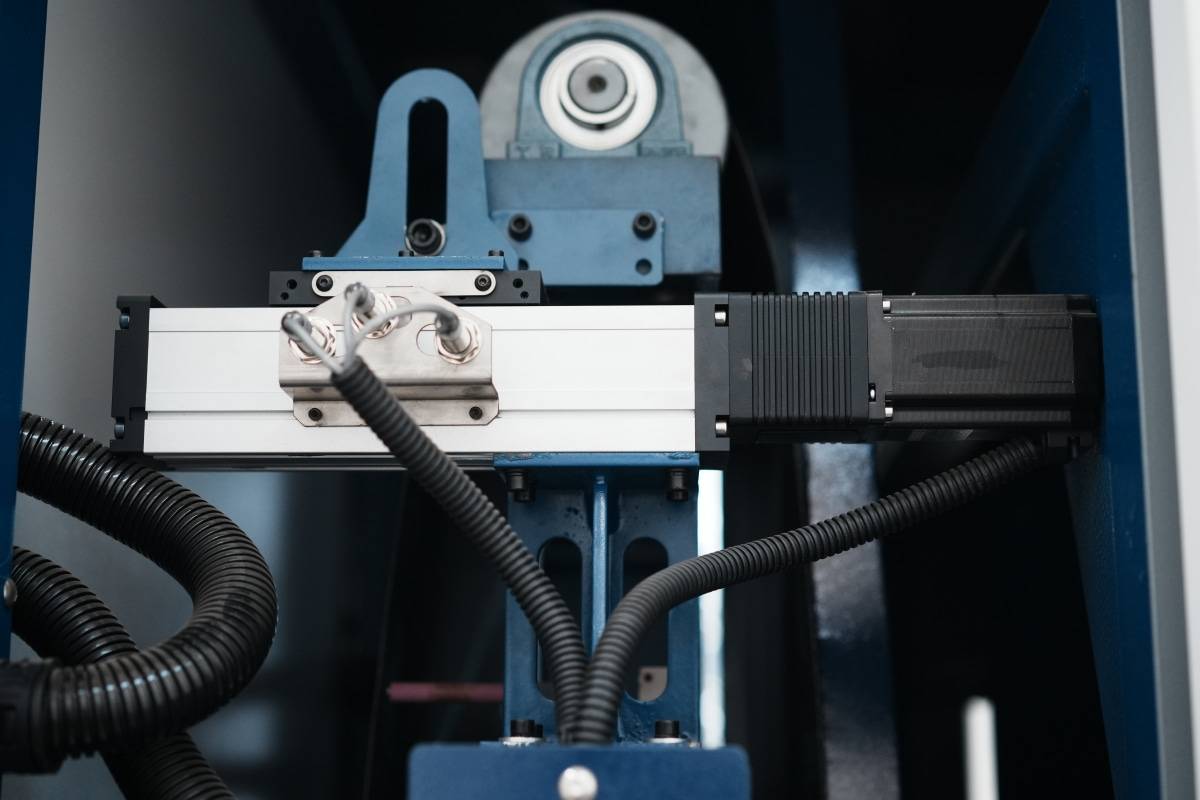

• Wide-abrasive belt configuration (300-800mm width)

• Longitudinal arrangement with auto-tensioning system

• Multi-axis pressure control (0-50N/cm²)

• Simultaneous deburring & polishing functions

• ±0.01mm precision surface treatment

• Adaptive material hardness handling (HRC 20-65)

As a manufacturing factory, we can offer you the best quality machines with an affordable price.

Every product is backed by a 5-year guarantee for any quality issues.

When a breakdown occurs, our technicals are on call for both online & onsite correction.

All of the machines ordered by our customer will be delivered within 45 days.

All machines are inspected by our quality control department before being shipped out.

We will provide you with professional expert suggestions for your required machine.

– Standard delivery time is 25 days.

– For custom machines, delivery may take 35-45 days depending on specifications.

– T/T: 30% deposit, 70% balance one week before shipment

– L/C: 100% at sight (terms negotiable)

– MOQ: 1 unit. We accept OEM customization.

– Machines can be customized to your specifications (size, power, features).

– We guarantee machine performance matches sample specifications. Technical parameters are detailed in contracts.

– All machines undergo multi-day testing with customer materials before shipment.

– We provide a 1-year warranty with flexible extension options.

– Machines are secured in containers with steel wires to prevent movement during transit.

– Containers contain only your ordered machine.

– Critical components are protected with custom foam and shock-absorbing materials.

– Remote support: Engineers provide text/video guidance for minor issues.

– Warranty parts are shipped free of charge (local purchase recommended for faster replacement).

– On-site service for complex issues not resolved remotely.

– Local agent support in regions with representation.

– Yes, we offer on-site training at our facility.

– Remote training is available if travel isn't feasible.

– Training covers operation, maintenance, and troubleshooting.

– Freight forwarders calculate shipping costs.

– You can use our freight partner or your preferred provider.

– Costs depend on destination, shipping method, and container type.

– We provide manuals, operating instructions, circuit diagrams, and hydraulic schematics.

– Documentation is available in English and Chinese.

– CE and ISO certificates available upon request.

– Our sales team conducts detailed requirements analysis before quotation.

– We recommend configurations based on your specific needs.

– We never upsell unnecessarily - expensive machines aren't always the best solution.

– Sample testing available to confirm machine suitability.

Trusted by manufacturers in 120 countries worldwide

"The automated deburring system reduced our post-processing time by 40% while maintaining ±0.02mm consistency. The ROI was achieved within just 8 months of operation."

"DYYRENT's deburring solution for titanium components has increased our production yield by 28%. The precision meets aerospace standards we couldn't achieve manually."

"For our precision electronics enclosures, the automated edge finishing system eliminated micro-burrs that caused 99% of our short-circuit issues. Quality control costs reduced by 65%."

"Processing 5-ton steel plates used to take 3 workers 6 hours. With DYYRENT's heavy-duty deburring line, we now complete the job in 45 minutes with one operator. Game-changing technology."

"The mirror finish achieved on our surgical instruments meets the highest medical standards. DYYRENT's solution reduced our rejection rate from 12% to just 0.5%."

"For solar panel frames, the automated deburring line increased our throughput by 220% while maintaining perfect edge quality. The system paid for itself in just 7 months."

You will get a guaranteed response within 24 hours.