Core Technology Breakdown

Detailed demonstration of Dry High-Speed Polishing Machine adaptive grinding system achieving ±0.01mm precision

View Technical Specs

Explore our deburring solutions through professional engineering demonstrations

Detailed demonstration of Dry High-Speed Polishing Machine adaptive grinding system achieving ±0.01mm precision

View Technical SpecsSmart factory implementation with IoT-enabled quality monitoring system

View Case Study

| Model | HYT-4-48 | HYT-192-LGJ | HYT-0-768-LGJ |

|---|---|---|---|

| Control System | PLC, Inverter, Touchscreen (Optional) | ||

| Power (KW) | Main: 1.5 + Small: 0.37 | Main: 5.5 + Small: 0.75 | Main: 37 + Small: 3.7 |

| Grinding Troughs | 4-48 grids | 4-192 grids | 16-768 grids |

| Max. Bowl Speed | 180 r/min | 140 r/min | 120 r/min |

| Dimensions (mm) | 1350×1080×1380 | 2700×1450×1800 | 3320×2700×2400 |

| Weight (Kg) | 520 | 1700 | 6500 |

| Voltage | AC 380V, 3-Phase 5-Wire | ||

Laser-cut plywood crates with anti-corrosion VCI coating

IP67-rated waterproofing with real-time GPS tracking

Forklift loading with certified operators

ISO container locking with vibration sensors

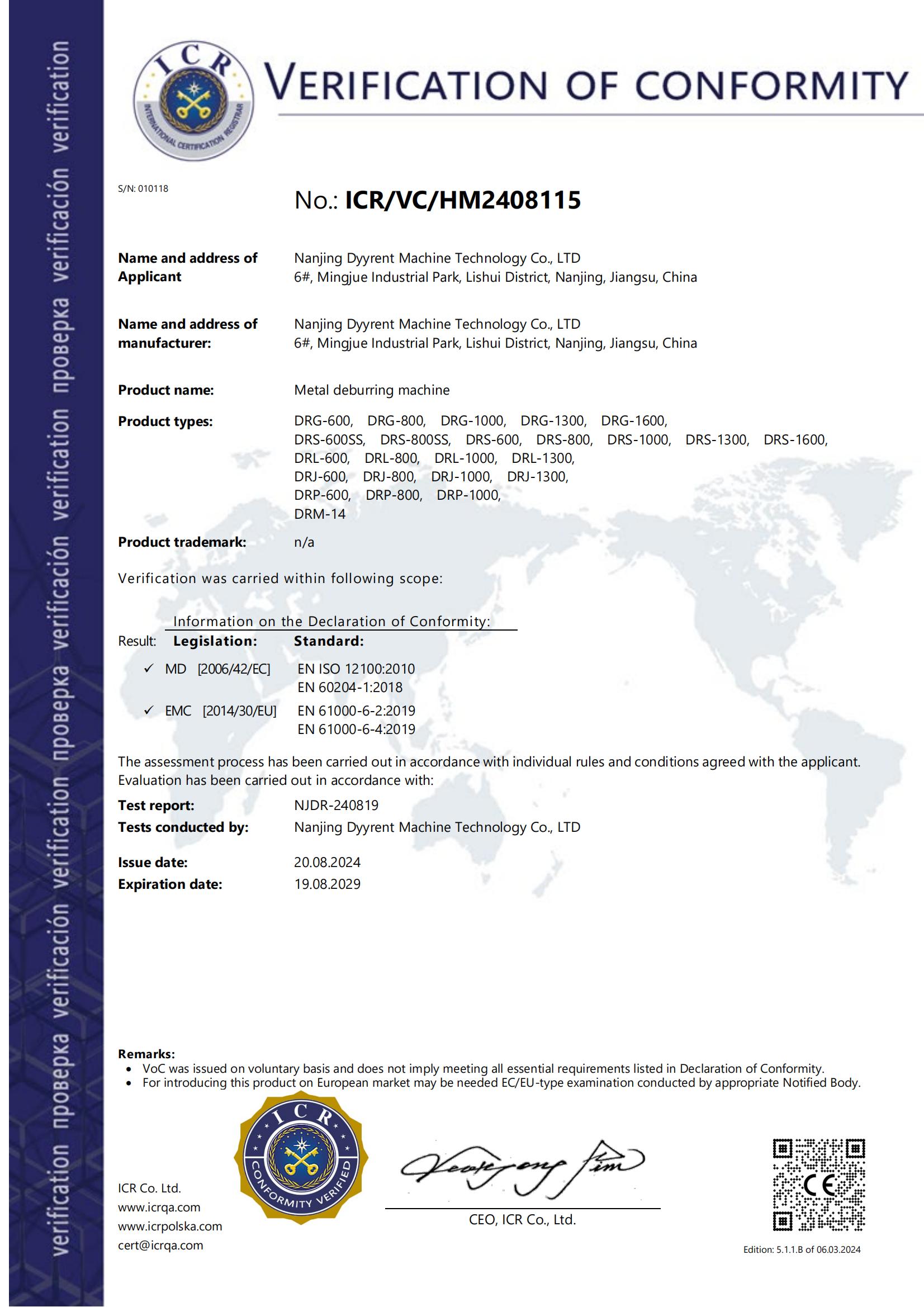

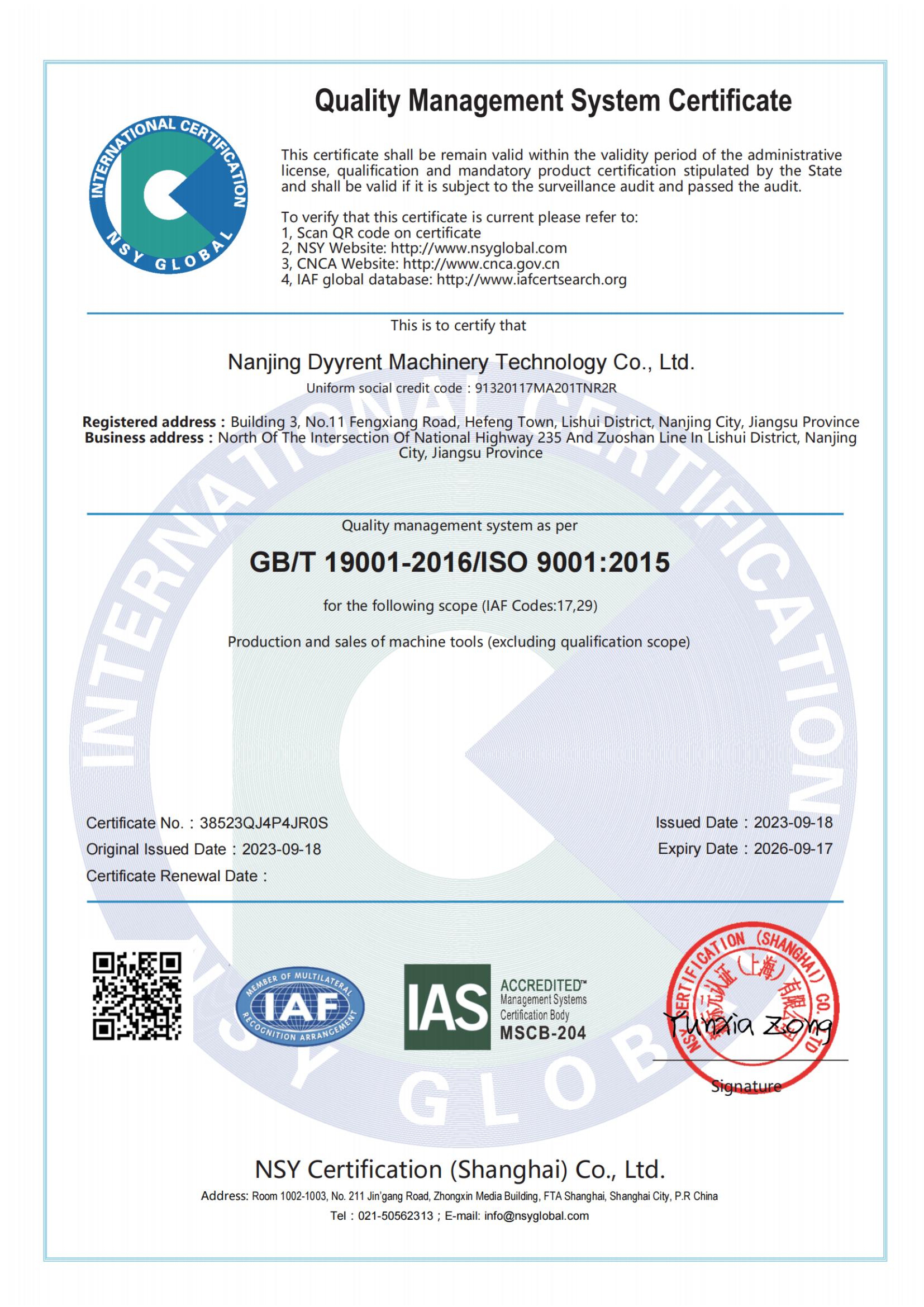

Complete export compliance documentation

100% quality check before departure

Trusted by manufacturers in 120 countries worldwide

"The automated deburring system reduced our post-processing time by 40% while maintaining ±0.02mm consistency."

"Achieved 99.8% defect-free turbine blades with the AI-powered quality control system."

"Sterilization compliance rate increased to 100% after implementing the automated cleaning line."

"Reduced microchip soldering defects by 75% with the precision temperature control system."

"Hydraulic cylinder production throughput increased by 220 units/day with automated assembly."

"Reduced material waste by 28% while increasing packaging line speed to 120 units/minute."

"Automated welding system cut hull assembly time by 35% with zero structural compromises."

"Increased solar panel production yield by 19% while reducing silicon waste by 22%."

Explore our 28,000㎡ smart factory featuring: