PRODUCT

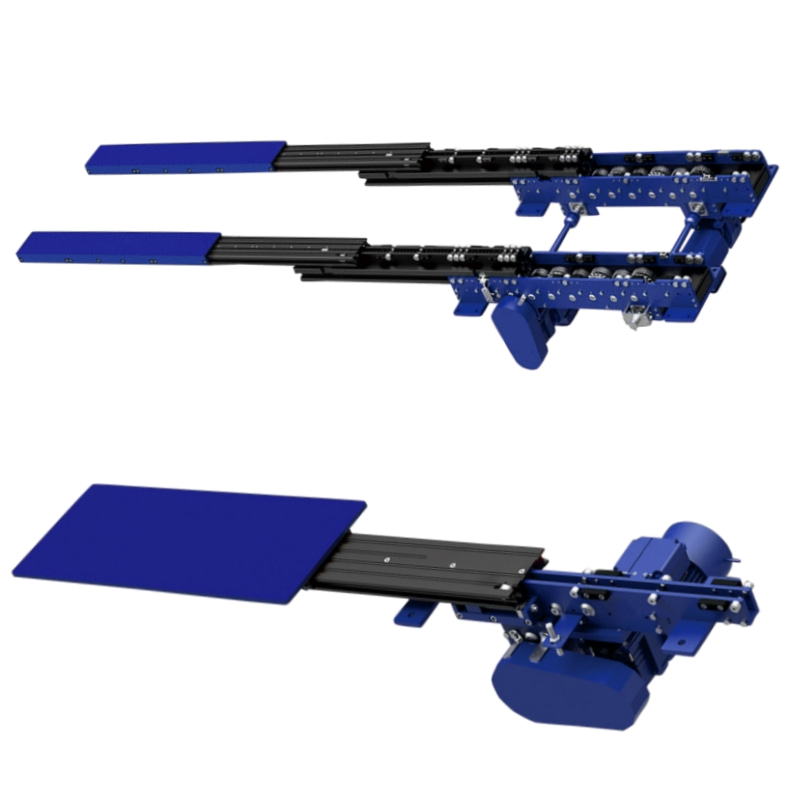

Telescopic Forks

High-Capacity Telescopic Forks for Warehouse Automation | DYYRENT Industrial Solutions

High-Performance Red Dual Fork Automation Solutions | DYYRENT Telescopic Reach Systems

Blue-Grey Double Fork Telescopic Systems | Precision Warehouse Automation Solutions

Precision Blue-Grey Single Fork Telespopic Systems | High-Density Warehouse Automation

Blue Single Fork Telescopic Systems for Narrow-Aisle AS/RS | Warehouse Automation

Industrial Blue Double Fork Telescopic Systems | AS/RS Warehouse Automation Solutions

SUPPORT

Technical Documentation

DYYRENT DRG Series: Precision Redefined in Metal Finishing

DRJ Series Deslagging Machine: Advanced Slag Removal Solution for Precision Manufacturing

DRL Series Polishing & Wire Drawing Machine: Precision Surface Finishing for Global Industrial Excellence

DRP Series Edge Rounding & Deburring System: Precision Surface Finishing for Global Industrial Excellence

DRS Series Abrasive Belt Deburring System: Precision Oxide Removal & Surface Finishing for Global Manufacturing